Introduction

Introducing the BobTail®, the epitome of advanced fastening technology. Designed to tackle the demands of diverse assembly applications, the Huck® BobTail® combines safety, quiet operation, and a unique pintail-less design. This exceptional fastener delivers unmatched performance and reliability. Available in various sizes, both in Grade 5 and Grade 8, the BobTail® meets the challenges head-on, ensuring secure and efficient fastening solutions.

What are the Advantages of Using Huck® Bobtails®?

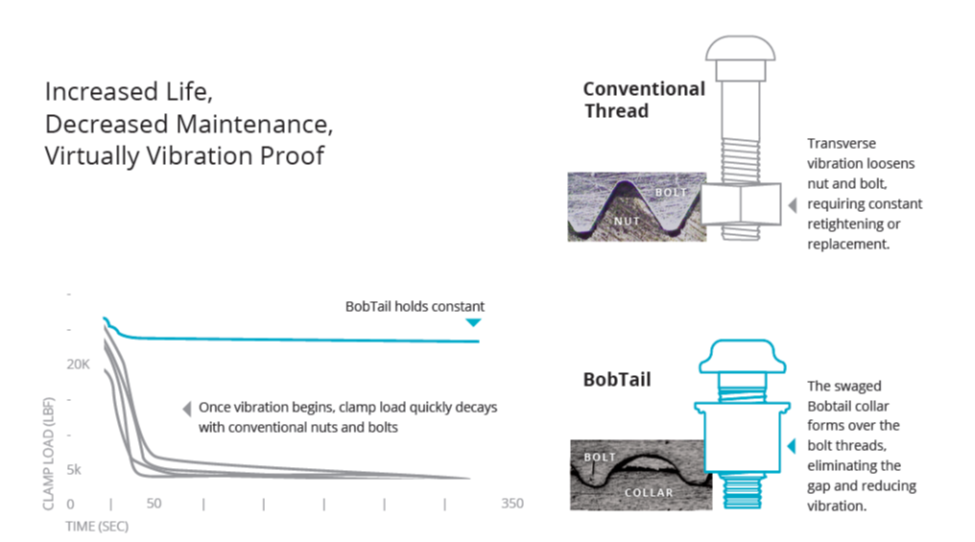

With Huck® BobTail®, fasteners can be securely installed in under two seconds each, providing unparalleled installation efficiency. Moreover, Huck® BobTail® exhibits exceptional fatigue strength, exceeding conventional nuts and bolts by a factor of five.

The BobTail stands out with its unique, no-break-off pintail, providing exceptional corrosion resistance in its class. It incorporates advanced, low-swage technology that allows for easy installation with a lightweight and ergonomic Huck® Bolt® tool. When considering the total cost of blind fasteners, including installation and inspection labour, the BobTail often delivers a lower overall installed cost.

Here are some advantages of using Huck® Bobtail® for easy and everlasting impact.

- Rapidly Installed: Typically completed in less than two seconds

- Innovative low-swage technology enables lightweight, ergonomic tooling.

- The no-break pintail stands out for its exceptional corrosion resistance, ranking as the best in its class.

- Rapid visual examination guarantees a high-quality connection.

Huck® Bobtail® Installation Process

Huck® Bobtail® uses an easy installation process to give quick and lasting efficiency. Here are some installation advantages that Huck® Bobtails® provide.

- The pintail-less design provides several advantages. It reduces noise and eliminates waste, resulting in improved corrosion resistance.

- The installation indicator offers a visual representation of the successful installation process.

- The collar material is permanently and vibration-proof connected by swaging it into the lock grooves.

- Using low-swage technology, tooling is faster and lighter, and the ergonomically designed tooling improves longevity.

The easy installation process requires less time and lasts longer, saving time and energy. The four-step process is easy to understand and follow.

- Secure the collar onto the pin by placing the pin in the designated hole, then rotating the collar onto the pin.

- The installation Huck® Bolt® tool is designed for annular pull grooves. Upon activation, a puller located in the nose assembly draws the pin into the Huck® Bolt® tool, causing the swaging anvil to apply pressure on the collar, effectively closing any gaps in the sheet metal component.

- Upon reaching a predefined force, the anvil initiates the swaging process, driving the collar into the pin’s lock grooves. This continuous swaging action extends both the collar and the pin, forming a precise and secure clamp.

- Upon completion of swaging the collar into the pin lock grooves, the tool facilitates the ejection of thesefasteners and releases the puller, thus completing the sequence.

Conclusion

With no gap in the metal-to-metal contact, Huck® Bobtail® provides a secure connection that works even in the severest environments. Having tight security, the swaged Bobtail collar forms a connection that resists vibrations and lasts for years.

With the ease of installation, the Bobtail sets a new standard for utility and productivity. With its cost-effective and time-saving qualities, the Huck® Bobtail® represents a new class of Huck Bolts®.