What are Blind Sheet Metal Fasteners?

Blind fasteners are a type of metal fastener. They are also called “blind rivets” or “blind bolts”. These blind metal sheet fasteners are used to join two overlapping sheets of metal.

Huck® Magna-Bulb®

Huck Magna Bulb® blind sheet metal fastener perfect for lower strength or thin sheet joint materials. It gives high Mechanical Performance (Best in class). Very high shear strength and high tensile strength.

- Seizes the joint with clamp

- Consists Magna Bulb® – Blind fastener of two pieces, called mandrel and sleeve

- Mandrel is heat treated, with rolled pull grooves

- Mandrel contains shear ring to bulb sleeve

- Sleeve material is softer than pin

- Sleeve is band annealed to facilitate formation of bulb

- Installs with special tool

- Pin lock retains pin

- Pin breaks flush with head of sleeve

Preparation

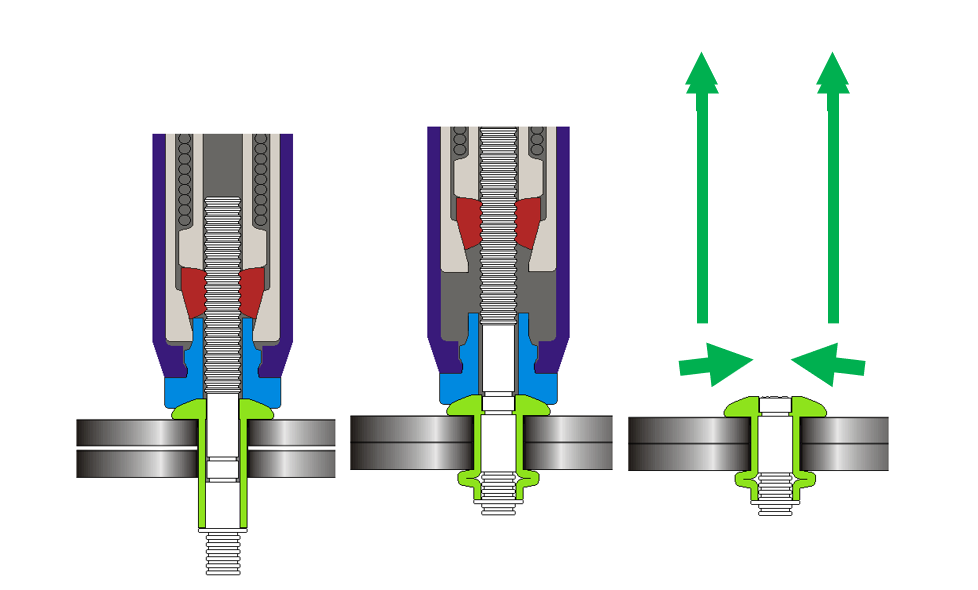

- Insert mandrel and sleeve into hole

- Insert mandrel into nose assembly

- Jaws ratchet over mandrel until insert contacts the sleeve

Installation

When trigger is engaged:

- Jaws pull mandrel

- Mandrel draws through sleeve, beginning to form bulb on backside

- Bulb forms, providing bearing area

- Shear ring breaks free and presses on catch grooves

- Mandrel shoulder hits sleeve lock and forces material into pin lock pocket

Tool ejection

- Jaws continue pulling

- Mandrel breaks at breakneck

- When trigger is released, nose assembly frees from sleeve

Use in applications that require:

- High shear strength

- High tensile strength

- Consistent clamp (compared to other blind fasteners)

- Loosening resistance in vibration situations

- Broad blind side bearing surface

- High pullout strength, esp. with mis-aligned, oversized or out of round holes

- Pull through resistance on thin materials

- Back side clearance

- Flush pin break

Refer to current industries

- General manufacturing

- High vibration applications

- Commercial truck body assembly

- Seat track

- Engine enclosures

Special features against blind fasteners for metal

Extra large blind side footprint: Ideal for lower strength or thin sheet joint materials

Structural fastener: It provides high tensile strength and very high shear strength

Flush pinbreak: The blind side of fasteners are free from catching on clothes, skin or goods. No special tool required for checking the installation but it gives Quick and easy visual inspection

Internal pin locking mechanism: Secure within the rivet body and protected from corrosion

Headstyles: Protruding

Materials: Steel

A Unique Bulbing Fastener with High Shear Strength

Huck Magna-Bulb® is a unique, clamp-type blind fastener offering high shear strength in specific applications. Its bulbing action during installation spreads the load over more surface area. Post installation, this blind fastener supplies stronger, longer-lasting connection. Thus Magna Bulb® blind fastener offers superior blind side strength.

This increased bearing area makes Magna-Bulb-blind fastener ideal for pullout resistance in thin materials, and oversized or misaligned holes. Positive, mechanical pin-retention ensures structural integrity no matter what the application.

Secure, Fast Installation

- Shear ring design promotes bulb formation and grip adjustment for flush break throughout the grip range

- The wide blind footprint (bulb) gives the fastener a broader bearing surface, spreading the load out for greater strength and high pull out resistance

- Unique solid circle lock ensures maximum strength and resistance to vibration

- Breaking flush throughout the entire grip range, the Magna-Bulb fastener eliminates costly cosmetic finish work. Simple visual inspection ensures that the fastener is installed correctly.

Installation Sequence

Application picture (where there is no access in blind side)

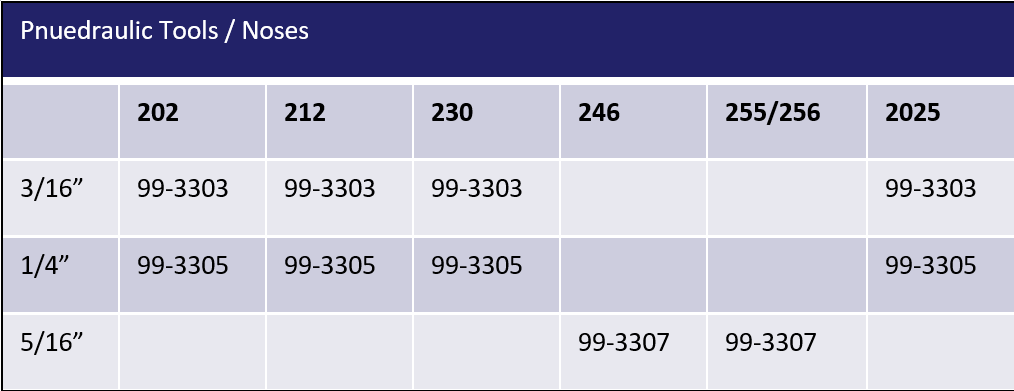

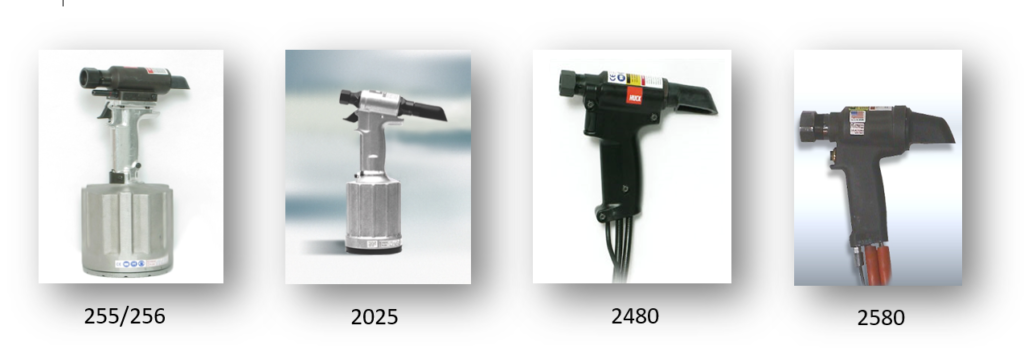

Tools for Magna Bulb® – Blind fasteners installation: