Recoil® wire thread inserts are widely used by major manufacturers in a variety of markets: including automotive, electronics, aerospace, military, power generation and manufacturing equipment.

Recoil® wire thread inserts are widely used by major manufacturers in a variety of markets: including automotive, electronics, aerospace, military, power generation and manufacturing equipment.

Marson® offers a full line of blind rivets in a wide variety of materials. Products include standard open-end rivets and specialty rivets, including Closed-end, Multi-Grip and Plastic rivets

Keenserts® are used in alloys, light materials, steel and cast iron to increase the strength of the thread in these materials.

Camloc ®, one of the most comprehensive ranges of Quick Release Fasteners available

It’s a combination of Power rig, high pressure hydraulic hose, installation tool and nose assembly provides for the high-speed installation of a wide range of HuckBolt and Huck blind bolt fasteners

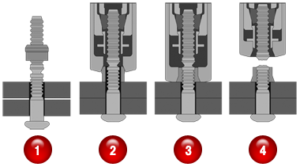

Huck® lock bolt and structural blind fasteners are designed to provide permanent, vibration-resistant joining solutions that result in consistent installations, time after time.

Huck®, Camloc®, Marson®, Recoil® is a brand owned by Howmet Fastening Systems (erstwhile Arconic Fastening Systems) , a leading designer and manufacturer of high-performance, proprietary fasteners and fastener installation systems.

We’re always interested in new projects, big or small. Please don’t hesitate to get in touch with us regarding your requirement.

![]()

4/1/4, Olabibitala 1st bye Lane, Howrah, WB 711104

Call now : +91 9831045458

Unlike any other fastener in the world, HuckBolts® are precision engineered two-piece fasteners that, once installed, never come loose. No matter how vibration-intensive the environment, HuckBolts® stay put. HuckBolts® provide direct metal-to-metal contact when installed, which eliminates the transverse vibration often found in conventional nuts and bolts. Engineered for a wide range of applications, HuckBolts® deliver superior joining strength, shear, and tensile strength for an unmatched fastening solution.

Recoil®‘s range of quality wire thread inserts enable you to produce strong, permanent threads in metals and plastics but are particularly useful for creating strong threads in softer materials such as aluminium, titanium and magnesium alloys.

The Recoil® range of wire thread inserts and thread repair products are especially designed to enable you to produce strong threads in weaker .sdaerht degamad fo riaper tneic fife dna tsaf tuo yrrac dna slairetam, Developed from decades of engineering experience, Recoil® products carry a global reputation for delivering fast, reliable and cost effective means of thread strengthening and thread repair.

Camloc® brings together 75 years worth of experience, traditional engineering skill and an innovative approach to produce our successful range of fasteners.

Our comprehensive range of products have for decades been providing customers with effective, reliable and creative solutions for applications in electronics, industrial, transportation, green energy, aerospace and defence markets

Our dedicated engineering team can adapt existing products or develop customised solutions to meet diverse and constantly changing industrial demands.

For a stronger thread

KEENSERTS® stainless steel inserts and studs provide strong, permanent metal threads in a range of ferrous and non-ferrous metals. A thread locking feature is available.

Benefits: